TODO

- Schematic

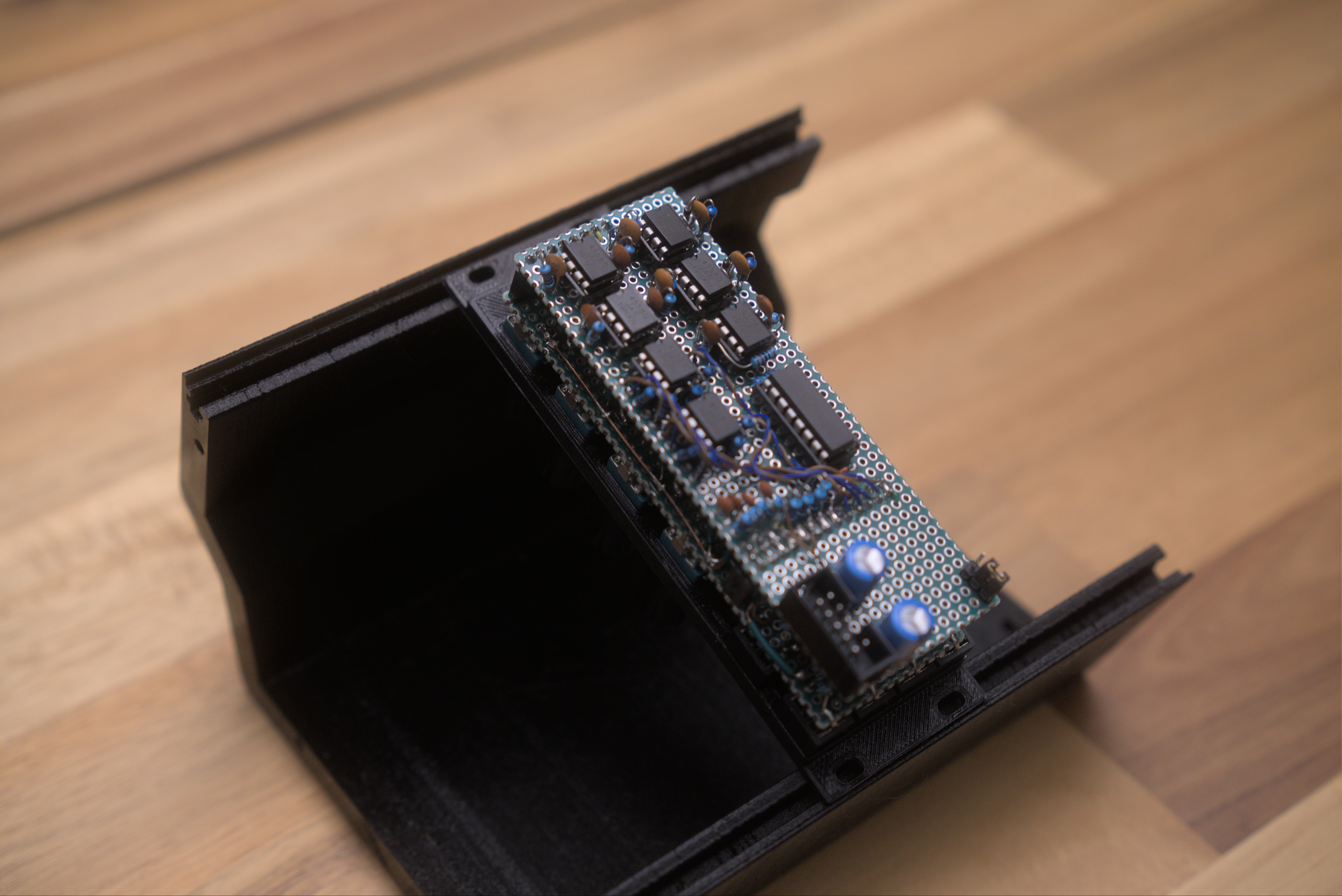

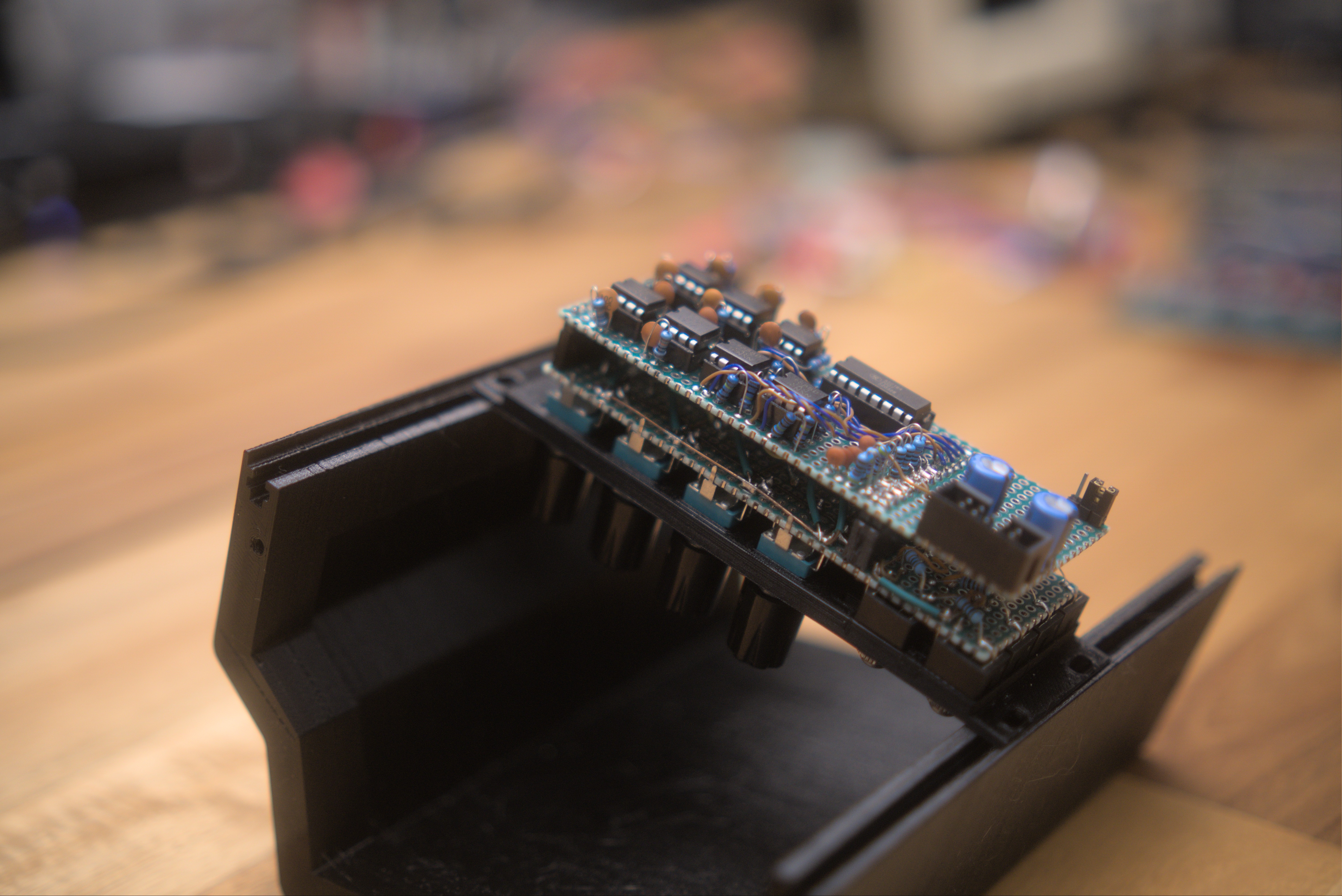

- Prototype

- PCB Design

Introduction

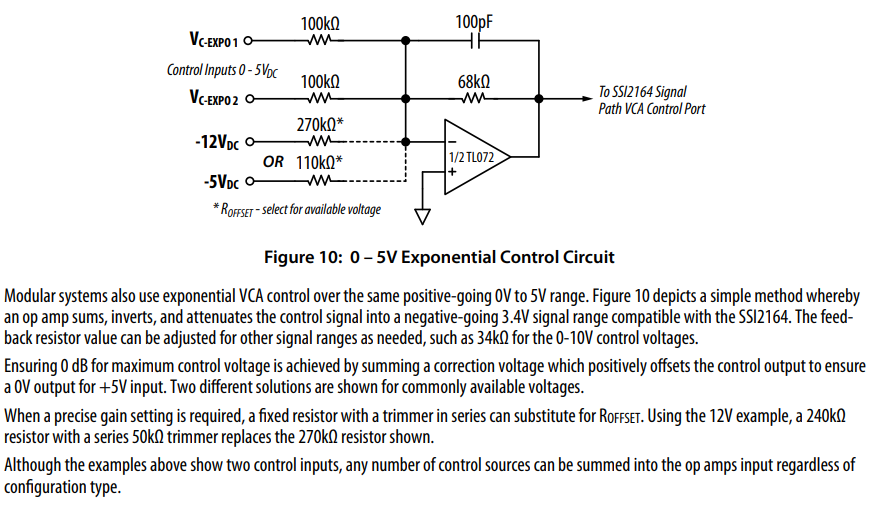

This module is a simple Quad VCA design. The design is based on the chip’s datasheet info.

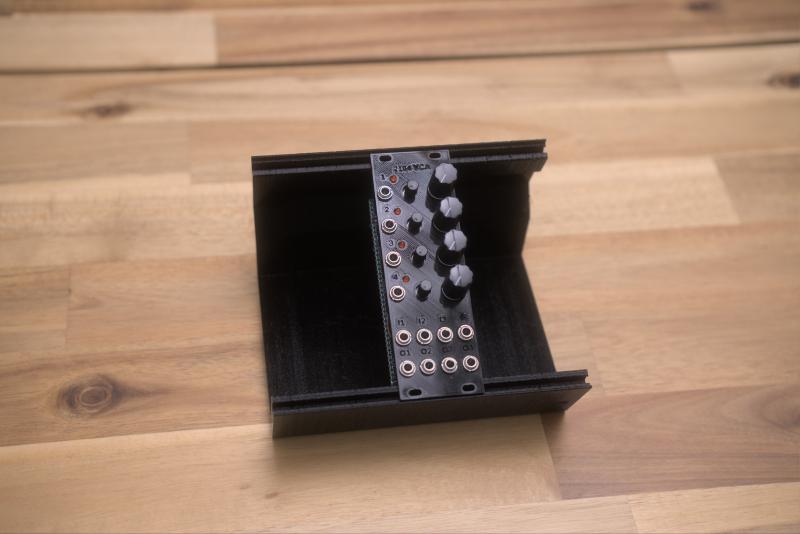

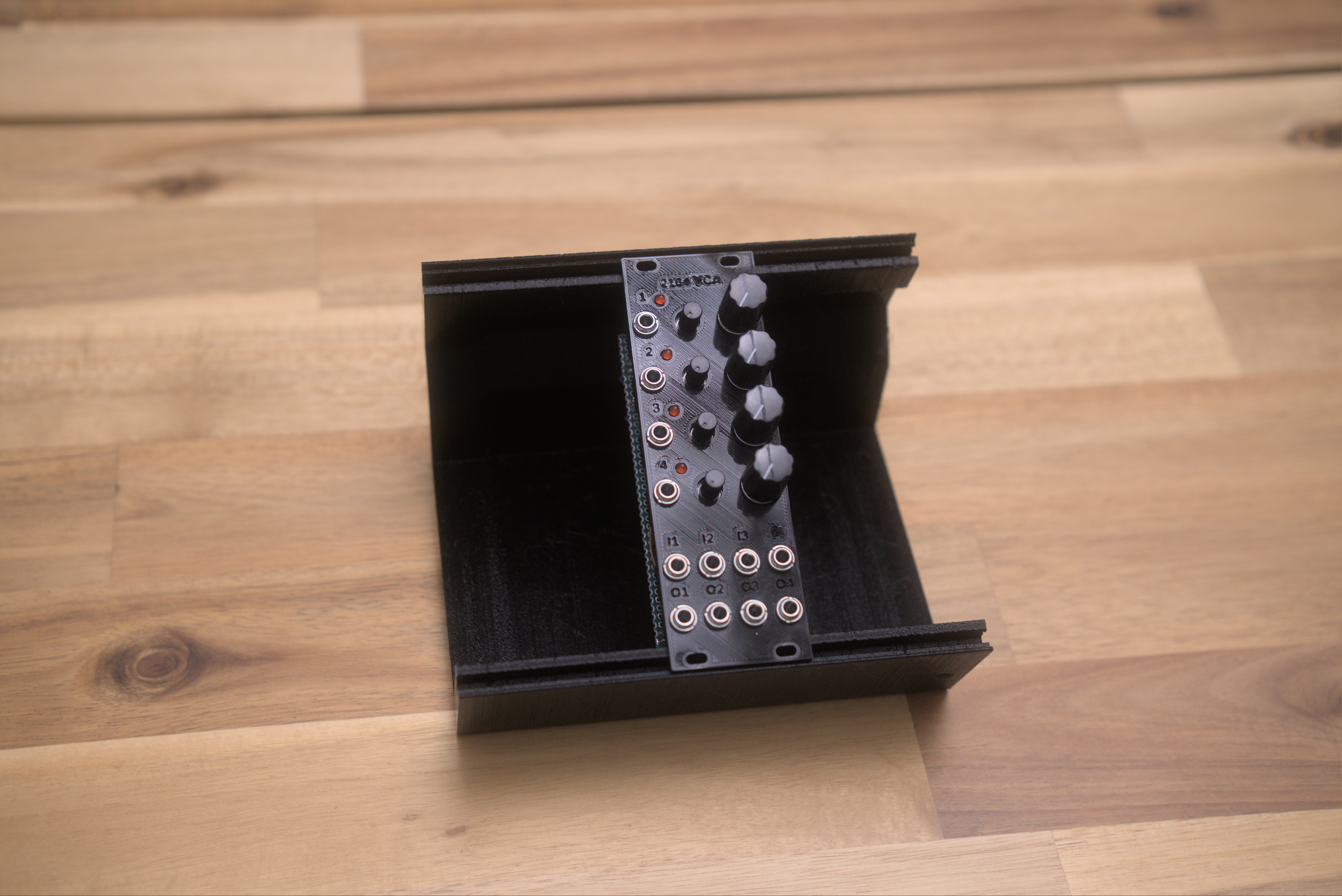

Module Images

Demo

Module Features

Four exponential voltage controlled VCAs.

Each CV input is normalled to the next. CV1>CV2>CV3>CV4 Each Signal input is normalled to the next. IN1>IN2>IN3>IN4

The 4th output jack can be switched to either the 4th VCA output or the mix output using a jumper.

I/O and Controls

Each VCA channel will have:

- Control voltage input (10vpp)

- Input attenuation knob

- Control (when no cv) / offset knob (when cv signal is present)

- Signal input (audio or CV signals)

- Signal output

Design Notes

Designing the cv input circuit

https://www.analog.com/media/en/technical-documentation/data-sheets/SSM2164.pdf

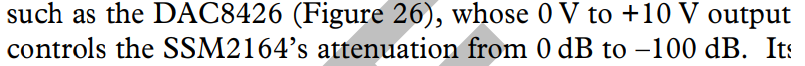

Control voltage and gain/attenuation

- Unity gain = 0v control voltage

- -100dB of attenuation = +5v control voltage

With that, a control voltage of 0 to 5v is optimal. We can just invert the input using an inverting op amp.

Another design decision that I would like to add to the module is normalling both cv and audio inputs to the next vca. I1>I2>I3>I4, CV1>CV2>CV3>CV4 when nothing is connected to multiply whatever is connected to the first input.

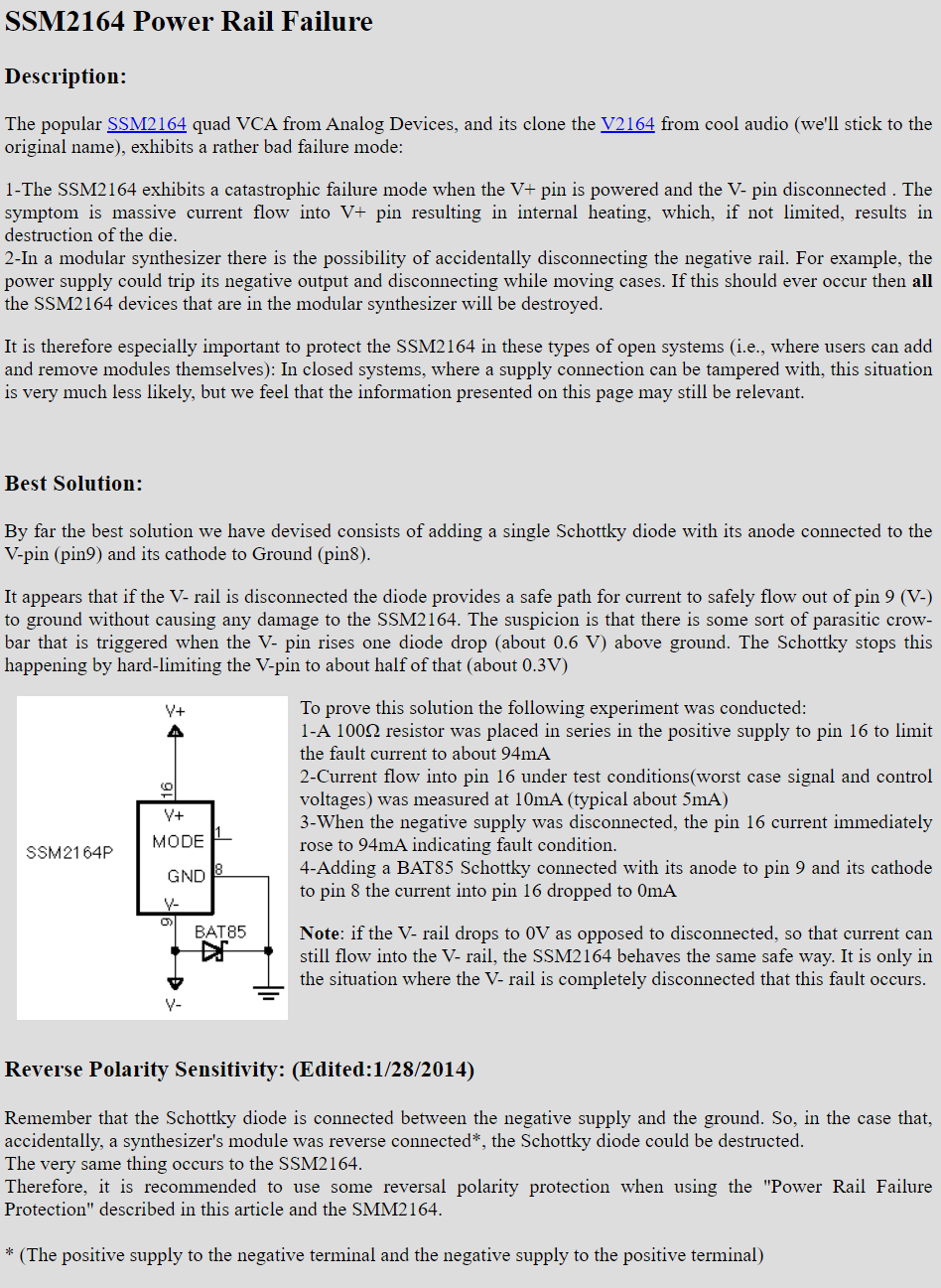

Protection from no negative power supply

Using the SSI 2164 datasheet CV input circuit

2164 chip voltage and attenuation relationship (Inverse) based on the ssi2164 datasheet

- 3.4V = Mute

- 0V = unity gain Datasheet circuit

- sums, inverts, attenuates the control voltage input

Falstad simulation link

Resources

- http://www.sdiy.org/philgallo/mgbvca.html

- https://doepfer.de/a1324.htm

- https://modwiggler.com/forum/viewtopic.php?t=96486

- http://electronic-sea.net/SSM2164.html

- https://www.amazingsynth.com/parts/ssi2164/ssi2164-datasheet.pdf

Schematic

Conclusion

If you’d like to build this module, I have provided a 3D printed front panel file in the repo. I used readily available green perfboard. The components should line up with the perfboard’s holes. The panel was made using benjiaomodular’s europanelmaker.